AEROSPACE

The aerospace industry is a global powerhouse, and South Yorkshire, England, has positioned itself as a key player in its continued growth and development. This region boasts a unique combination of cutting-edge research facilities, industry giants, and a highly skilled workforce, making it a prime location for aerospace businesses.

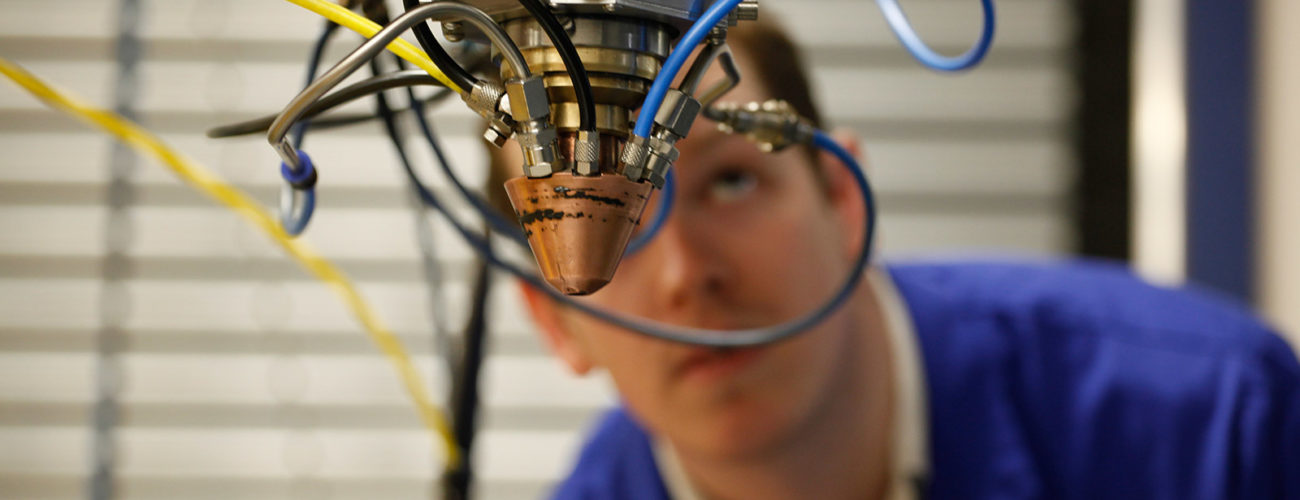

The longstanding partnership between the University of Sheffield's Advanced Manufacturing Research Centre (AMRC) and Boeing, a leading aircraft manufacturer, exemplifies this strength. This collaboration has not only fuelled innovation but also established a robust local supply chain for Boeing parts. South Yorkshire excels in the machining and manufacturing of titanium, a critical material in aerospace engineering. The AMRC's successful research collaboration with Messier-Dowty, a UK manufacturer, is a prime example. Their joint efforts played a significant role in securing the prestigious contract for Boeing's Dreamliner landing gear.

Furthermore, South Yorkshire is a hub for pioneering companies pushing the boundaries of material technology. Metalysis, a company specialising in world-leading solid-state alloy powder technologies, relocated from the "golden triangle" to Sheffield. This move highlights the region's attractiveness for innovative firms seeking a supportive environment. Metalysis joins a growing cluster of high-value aerospace component manufacturers, further solidifying South Yorkshire's position at the forefront of aerospace materials development.

AMRC Castings, along with its commercial arm Casting Technology International, stands out as the UK's sole titanium melting facility. This entity boasts an impressive track record, having delivered Europe's largest single ceramic shell titanium casting. The success stories extend beyond regional borders. The AMRC's collaborative efforts with Boeing have garnered international recognition, being singled out by Forbes magazine as a model partnership between academia and industry.

Adding to South Yorkshire's impressive credentials are the establishments of world-class facilities by industry giants. In 2015, Rolls-Royce unveiled their £110 million Advanced Blades Casting Facility, a testament to the region's commitment to cutting-edge technology. This state-of-the-art facility utilises robots and automated inspection systems to manufacture a remarkable 100,000 turbine blades annually for Rolls-Royce's Trent aero-engines.

Boeing followed suit in 2017, announcing the construction of its first European production facility in Sheffield. This pioneering plant leverages the expertise of regional apprentices while incorporating smart machining and digital technologies developed by the AMRC's research teams. Boeing's commitment to the region extends beyond manufacturing. They have recently announced a collaboration with Zero® to test the next generation of sustainable aviation fuels (SAF) at the University of Sheffield's Energy Innovation Centre (EIC). This initiative underscores South Yorkshire's dedication to fostering a sustainable future for the aerospace industry.

For further details or to discuss the potential for investment and partnership opportunities, please contact invest@southyorkshire-ca.gov.uk.